Recently, a research team led by Principal Investigator of the National University of Singapore Guangzhou Research Translation and Innovation Institute (NUS GRTII), Assistant Professor at the NUS School of Computer Science, and Co-founder & Chief Scientist of the embodied AI company RoboScience, Lin Shao, has introduced ShapeForce, a low-cost, “plug-and-play” alternative to force-torque sensors. With a material cost of only around $6, it delivers performance comparable to commercial sensors costing thousands of dollars.

Equipping Robots with a “Sense of Touch”: Decoding ShapeForce Technology

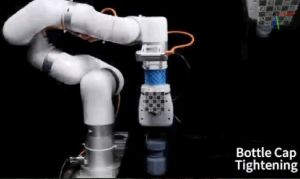

Humans effortlessly screw on bottle caps or pick up objects not by precise numerical values, but through intuitive perception of force and torque changes at their fingertips. However, enabling robots to replicate this “sense of touch” and adjust their strength and direction accordingly has primarily relied on sophisticated six-axis force-torque sensors. These sensors, often priced at thousands of dollars, have limited widespread adoption across various technological applications due to their high cost.

ShapeForce achieves a breakthrough at a material cost of approximately $6. It can be easily manufactured using 3D printing and integrated with an RGB camera for perception, allowing robots to acquire force-sensing capabilities rivaling commercial sensors at an extremely low cost, making them competent for various intensive contact tasks.

The core principle of ShapeForce is to convert externally applied forces and torques into measurable deformations of its own compliant structure. This is followed by estimation through marker-based pose tracking, converting the data into force-like signals. This enables robots to perceive the occurrence and changes of contact and adjust their motions in real-time.

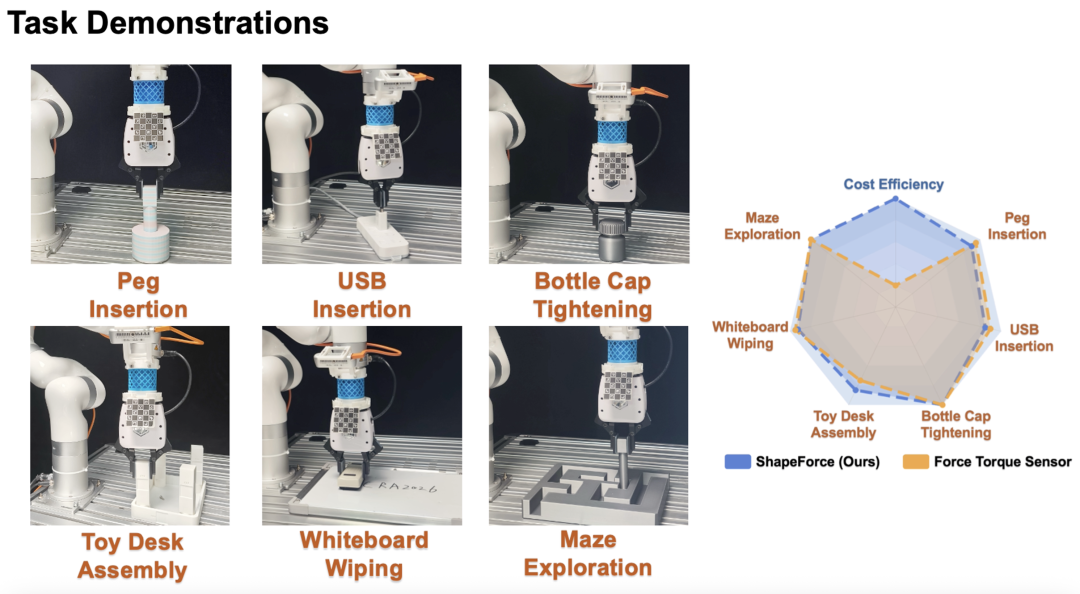

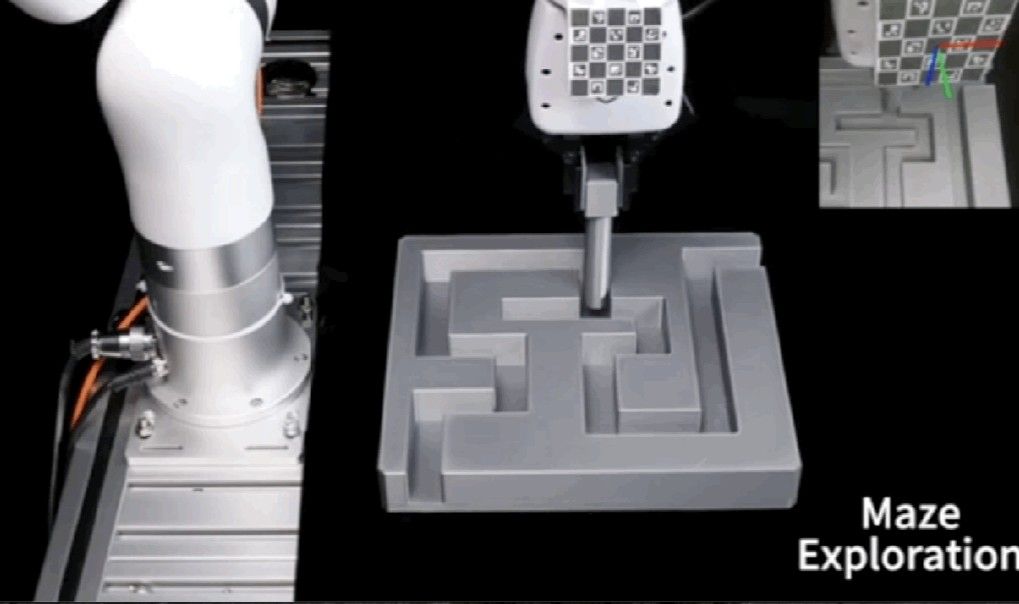

Experiments such as maze navigation, USB port insertion adjustments, bottle cap tightening, and precise plugging have demonstrated ShapeForce’s excellent performance and perceptual capabilities.

Furthermore, the structural compliance of ShapeForce significantly enhances the system’s robustness and fault tolerance in high-precision tasks. It can tolerate minor errors in such tasks, substantially improving the success rate.

In summary, by drawing inspiration from human intuitive force perception, ShapeForce successfully circumvents the cost and complexity barriers of traditional force-torque sensors. Not only does it achieve performance comparable to commercial products with a low-cost solution, but its core focus on “perceiving relative force changes” also provides a simple, robust, and easily accessible new technological pathway for dexterous robotic manipulation. This holds the potential to truly advance intelligent robots from “perceiving the environment” to “dexterous interaction.”

RoboScience

The embodied AI company RoboScience was co-founded by NUS Assistant Professor Lin Shao and former Apple researcher Tian Ye. It has completed seed and angel rounds of financing. In November 2025, RoboScience was recognized by the Silicon Valley authority The Information in its “The Information’s List of the 50 Most Promising Startups” (TI50) list and was included in Gaogong Robot’s “2025 Top 10 Most Investment-Potential Startups,” receiving high recognition for its development potential within the industry.