The NUS Guangzhou Research Translation and Innovation Institute (NUS GRTII) is dedicated to creating an interdisciplinary and cross-sectoral platform for scientific research exchange, fostering the effective translation and application of research outcomes. We will regularly share cutting-edge research findings and updates in this section and welcome discussions and exchanges.

This article presents research on the customizable mechanical properties of new steel materials for additive manufacturing, conducted by Dr. Sing Swee Leong. He was appointed Assistant Professor in the Department of Mechanical Engineering at the National University of Singapore (NUS) in August 2021 and is currently also a PhD supervisor at the NUS GRTII.

1. Research Background

Additive manufacturing (also known as 3D printing) is an advanced manufacturing method that builds complex, high-performance metal components layer by layer. Compared to traditional forming processes, it offers significant advantages in fabricating intricate shapes. The metallurgical characteristics of additive manufacturing—such as high cooling rates and thermal cycling—provide unique opportunities for customizing material properties, enabling direct control over the microstructure and mechanical properties of materials. However, conventional additive manufacturing powder materials are not specifically designed or optimized for these metallurgical characteristics and typically require post-processing heat treatments to improve their microstructure after fabrication. This limitation somewhat restricts the potential for performance customization. In this study, an Fe–Ni–Ti–Al maraging steel with rapid precipitation characteristics was selected to fully leverage the potential for in-situ microstructure control during additive manufacturing, thereby achieving customizable mechanical properties without the need for post-processing.

2. Research Content

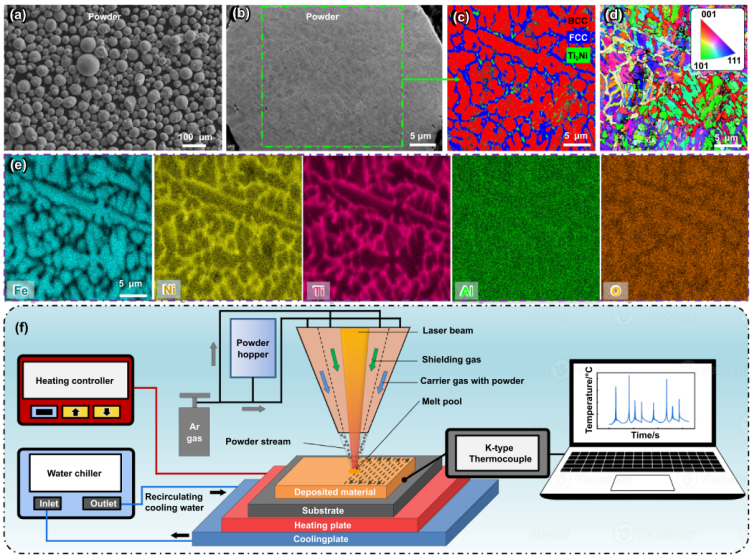

This study focuses on optimizing the Laser-Directed Energy Deposition (LDED) process for Fe–21.1Ni–6.3Ti–1.3Al (wt.%) maraging steel, aiming to achieve tunable mechanical properties by controlling the thermal history during deposition. The initial structure of the Fe–21.1Ni–6.3Ti–1.3Al maraging steel powder is shown in Fig. 1 (a–e). Additionally, a specially designed LDED setup with heating and cooling plates was used to control the temperature field, as illustrated in Fig. 1 (f). This research explores various deposition methods to regulate the thermal history and induce specific microstructural and phase transformations to adjust the mechanical properties of the steel, including strength and ductility. The main innovative deposition methods investigated in this study include:

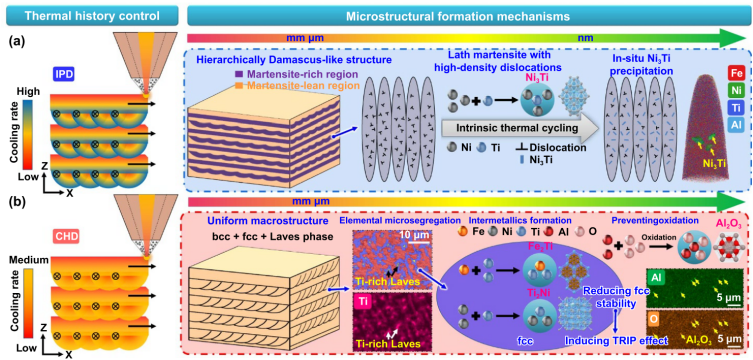

Interlayer Paused Deposition (IPD): This method introduces controlled pauses between layers during the LDED process. By extending these pauses, the accumulation of heat can be managed more precisely, allowing the material to cool before each layer is deposited. This controlled cooling rate directly impacts the thermal history, ensuring martensitic transformations occur during deposition, forming regions with high dislocation density, as shown in Fig. 2 (a). These regions further induce the in-situ precipitation of the η-Ni₃(Ti, Al) phase, enhancing tensile strength while maintaining a balance with ductility.

Constant Heating Deposition (CHD): In this method, the substrate is maintained at a constant high temperature (~200℃) throughout the deposition process. By keeping the substrate temperature above the martensitic start temperature, martensitic transformations are fully suppressed during deposition, thereby inhibiting in-situ precipitation (since precipitation requires martensite to provide a driving force). The schematic of microstructural evolution during CHD is shown in Fig. 2 (b). This strategy helps to achieve uniform phase and element distribution, reduces residual stress, and ultimately results in a more ductile structure.

Alternative Heating Deposition (AHD): AHD alternates heating and cooling between layers to create a hierarchical structure in the steel. This approach gives each layer a different thermal history, leading to varied phase compositions and microstructures between adjacent layers. The alternating thermal cycles promote the formation of regions with both hard and soft phases, thereby enhancing the overall toughness of the material. By introducing a thermal gradient within the layered structure, this method leverages unique phase transformations to improve the steel’s resistance to deformation.

By employing these targeted deposition strategies, this study analyzes the corresponding microstructural changes, focusing on the formation of primary phases like martensite and austenite, as well as the in-situ precipitation of secondary phases such as η-Ni₃(Ti, Al). Additionally, a detailed analysis was conducted on the size, distribution, and volume fraction of these phases and their contributions to the material's mechanical properties. For instance, regions with high dislocation density martensite improve strength, while the formation of η-Ni₃(Ti, Al) precipitates further strengthens the alloy by impeding dislocation motion. Conversely, due to the strain-induced transformation effect, austenite provides the material with good ductility and work-hardening capability.

Through the integration of these methods, this study provides insights into how thermal history control during LDED can be utilized to produce Fe–Ni–Ti–Al maraging steels with customizable mechanical properties, potentially broadening their application in fields requiring high strength and specific ductility.

▲Fig. 1. Materials and methods. (a)–(e) EBSD images and EDX mappings of the Fe–Ni–Ti–Al raw powder, (f) schematic of LDED with heating and cooling plates.

▲Figure 2. Schematic diagrams of microstructural formation mechanisms with thermal history control. (a) IPD and (b) CHD.

3. Key Achievements or Significant Discoveries

Jinlong Su, Qian Li, Jie Teng, Fern Lan Ng, Zheling Shen, Min Hao Goh, Fulin Jiang, Swee Leong Sing, Tao Yang, and Chaolin Tan. Programmable mechanical properties of additively manufactured novel steel. International Journal of Extreme Manufacturing (2024). (IF: 16.1, Q1, rank 15/355, Engineering, Industrial and Manufacturing Engineering)

4. Introduction of Project Leader/Project Team/Your Laboratory

Dr. Sing Swee Leong was appointed as an Assistant Professor in the Department of Mechanical Engineering at the National University of Singapore (NUS) in August 2021. Before joining NUS, Dr. Sing served as a Presidential Postdoctoral Fellow at the Singapore Centre for 3D Printing and the School of Mechanical and Aerospace Engineering at Nanyang Technological University (NTU), Singapore. His research interests lie in advancing material development through innovative manufacturing technologies and creating strategic value for industry. As of November 2024, Dr. Sing has co-authored over 100 peer-reviewed articles and several patents in the field of Additive Manufacturing (AM) or 3D Printing, with an h-index of 40. He also serves as an editor for several AM-related journals, such as Virtual and Physical Prototyping and Materials Science in Additive Manufacturing, and is on the editorial boards of journals like the International Journal of Extreme Manufacturing and International Journal of AI for Materials and Design.

▲Figure 3. Photo of Dr. Sing Swee Leong's Group

The NUS GRTII focuses its research efforts on seven key areas: smart cities, information and communications, electronics and technology, advanced manufacturing, artificial intelligence, biosciences, and financial technology. Leveraging the world-class research capabilities of NUS, the institute has recruited dozens of professors, associate professors, and assistant professors from NUS to serve as academic leaders. These experts lead local research teams in advancing scientific research, translating research outcomes, and conducting postdoctoral training programs.

We look forward to collaborating with global research experts, entrepreneurs, and policymakers to stimulate innovative thinking, explore the limitless possibilities of scientific research, and establish an interdisciplinary and cross-sectoral ecosystem for scientific research and innovation applications.